Insider Tips on Launching a Commercial Hydroponic Farm From Hydro Salad’s Founder.

Running commercial hydroponics farms differs significantly from growing hydroponics at home for passion.

The success of a commercial hydroponic farm depends on many factors. The only way to avoid painful failures is to consult an expert.

Anuradha Wasala is a young entrepreneur. His agriculture degree and experience in the largest automated hydroponic farm in Sri Lanka give him an edge. So, he decided to start his farm, Hydrosalad, in a 4000-square-foot polytunnel.

We wanted to talk to him and learn from him. It was one of the most valuable sessions for anyone wanting to start a commercial hydroponic farm.

We’ve discussed many things about his farm and experience in this short session. Anuradha has a rather unique perspective on modern farming techniques.

Anuradha believes soil-based agriculture will continue to be the best way to feed the world, especially in countries like Sri Lanka, where soil-based growing thrives. Anuradha also doesn’t seem to think indoor farming has benefits in equatorial countries.

Who’d want to put grow lights where sunlight is already abundant?

Yet, Anuradha has positive views about aquaponics. Talking about aquaponics led us to our first central topic.

What are the Commercially viable hydroponic systems?

Most hydroponic enthusiasts would have started growing something at home. And they’d have started with the Kratky method.

Kratky is an easy-to-do, soil-less growing technique. But it’s hardly a commercial hydroponics technique. Deep water culture (DWC) is an extended version of Kratkey. This is used in commercial hydroponics farms to grow crops.

There are several benefits of DWC. Yet, Anuradha prefers the Nutrient Film Technique (NFT) to grow lettuces.

Being able to control the water level and not needing to oxygenate them are his reasons for choosing NFT over DWC. Since DWC closes contact with the air, water must be externally oxygenated.

We then talked about Aeroponics. Aeroponics is too complex and costly to set up. These costs far outpace the benefits of lower water usage. It could be a good solution where water is in absolute scarcity, like in a desert or ice-covered Antarctica. But its complexity isn’t worth pursuing for most parts of the world.

Anuradha also has growers in his network who use DWC and aquaponics successfully. He doesn’t criticize the other methods but prefers NFT for its simplicity.

We were curious to know if NFT, DWC, and aquaponics were all commercially viable options and what other factors may ensure the success.

What ensures a profitable hydroponic startup?

This part of the discussion was fascinating. We knew we were asking a very open-ended question. But Anuradha has straightforward answers.

The key is thinking long-term.

Secure long-term contracts.

Anuradha has secured enough orders to cover his costs and beyond from day zero. This long-term contract gives him adequate flexibility in optimizing his costs. Further, he can take calculated risks with his investments. When the base is established, growth becomes the focus. Securing a few long-term contracts gives you all the freedom.

Strategically pick farm Location.

You must place your hydroponic farm closer to your market. The most significant savings come from transport and logistics for commercial hydroponics farms. The extreme of this is urban farming. But in Anuradha’s case, he doesn’t depend only on the local market. Instead, he placed his farm closer to his largest long-term client.

Grow crops with higher Margins.

Technically, you can grow anything in hydroponics. You need to control the environmental conditions with a greenhouse. But everything you buy in the market doesn’t have equal value. Due to market demand and supply, some crops may give you better margins. Anuradha’s target is premium lettuce for export. It gives him a greater margin, and this could offset occasional losses. Also, lettuce requires little care and labor compared to other crops like tomatoes.

Don’t overlook the knowledge.

Anuradha is a keen believer in learning. Hydroponics is more than a fancy technique. It has its risks. If someone plans a hydroponic startup, they must know the nitty gritty of running one. Compared to soil-based farming, hydroponics is a young and immature field. Thus, resources are limited. He was fortunate to join a hydroponic startup as an intern. Today, university students work with Anuradha as volunteers on his farm. Anuradha’s advice for hydroponic startups is that the only proper way of learning is by doing it.

This last part has brought us to talk about risks. More specifically, risks associated with NFT systems.

What Risks Are Involved in Running a Commercial Hydroponics Farm?

Talking about risks is particularly interesting. No business runs without any risks. Hydroponic farming is no exception.

Reliable Electricity

Anuradha says the reliability of electricity plays a crucial role in the success of a crop. Without the motors & fans working, crops may not survive even hours inside the greenhouse. He has backup motors ready and a generator to cover any power outage. We talked about installing solar power. But a small-sized farm couldn’t afford to cover its roofs with solar panels. But large farms may use solar to power the motors.

Accuracy of meter readings

Commercial hydroponics often rely on greenhouses, and it’s a controlled environment. If your meters go wrong, the results are catastrophic. Anuradha shared one of his learning points when he used a faulty pH meter in the ton farm. He had to throw a whole batch of lettuce for no good.

nutrient leakages

Nutrient solution is the most precious ingredient in hydroponic farming. Any leakage would cost the business a fortune. It’s sometimes hard to find out. But spotting them early would make a massive difference in the bottom line. The farm’s NFT channels and other equipment must be high quality to prevent such wastage.

Hydroponics isn’t a walk in the park. Without proper knowledge, building a Commercial hydroponics farm is next to impossible. This talk about risk and reward led us to discuss financial viability and payback periods.

How profitable are Commercial hydroponics startups?

For people thinking of a hydroponic startup, their first question may be how much space they need. The other most important questions are how much investment they need and how much they can make out of it.

Anuradha suggests at least 2500 square feet for commercial viability. Anything less is instead considered as growing for passion. We can grow around 4000 lettuce crops using NFT systems in such a space. Each lettuce plant would weigh about 150 grams at the harvest. So, we’re talking about some 600 kilos of lettuce. Since lettuce has a lifespan of around 30 days, this would be the monthly yield.

Most people freak out when they hear about the initial setup cost in hydroponics. Of course, greenhouses, NFT systems, water pumps, and exhaustion fans all cost a fortune. Yet, given the beautiful 600 kilos monthly yield, it is worth the investment.

How much exactly you make may differ from which part of the world you’re serving, the demand for lettuce at a given time, and more. But generally, a 2-3 years payback period is possible on hydroponic farms.

More space is generally better. If you have a 5000-square-foot greenhouse, you’d fully use the cooling pad, fan, and other infrastructure. While these costs are primarily constant, smaller farms waste a lot of potential.

The substantial initial investments in a hydroponic startup are land, the greenhouse, the NFT structure, water pumps, cooling pads, exhaustion fans, and measuring equipment. This brings us to our next question. How about the running costs?

Running costs of a Commercial hydroponics Farm

The fixed costs are a concern. But it dramatically offsets the running costs.

As mentioned, a commercial hydroponics farm can be in a cost-optimal location, like Anurdha’s strategically placed one near his most prominent client. Besides, a commercial hydroponic farm usually doesn’t need pesticides, and wastage is minimal.

Here are the significant running costs of a commercial hydroponics farm.

Electricity

NFT systems heavily depend on water pumps. Greenhouse temperature control depends on cooling pads and exhaust fans. All these need electricity.

Water

Soli-less farming is growing in water. But the good news is water is reused in hydroponics. Besides the water absorbed by the crops, every single drop is reused.

Nutrient

Many lettuce varieties need about 2 kilos of Albert solution per 10 liter of water. They may also need supplements for calcium, nitrogen, and iron.

Seeds

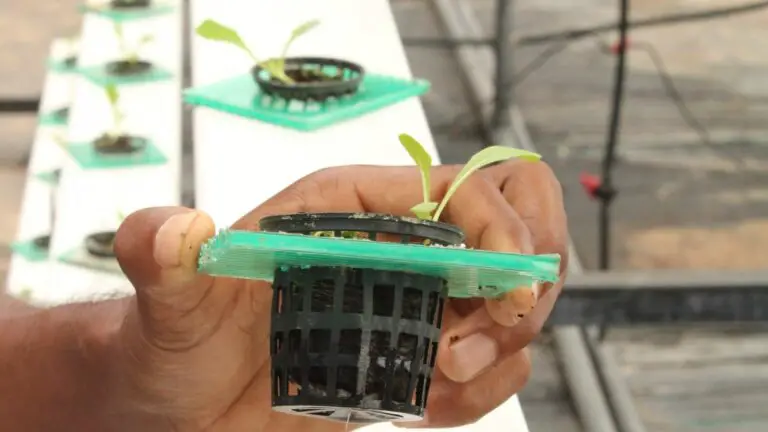

The correct seeds are crucial to run a commercial hydroponics farm successfully. Nearly 100% germination has a considerable cost benefit. Anuradha suggests high-quality crop seeds from Rijk Zwaan for hydroponic lettuces.

Growing Medium

Coco coir or coco peat may be economical for growing medium in coconut-producing countries. Anuradha uses both coco peat and chips as the growing medium. He says coco peat can handle pump failures for a little longer as it can hold water. However, the downside is that the coco peat is overly wet and may need to be squeezed to drain excess water.

Labor

Labor requirements in commercial hydroponics farms depend on what product you grow in there. Lettuces are easier to manage and harvest and need much less labor. Anuradha says he only needs one extra person to handle the harvest. But crops like tomatoes and strawberries need daily labor for harvesting season.

Beyond his hydroponic farm

Anuradha visits his farm daily to ensure smooth running. Meanwhile, he is adopting automation and precision agriculture practices to put the farm on autopilot. He already has automatic water circulation systems to start with.

He uses his extra time for research and consulting. He advises others to build greenhouses, start hydroponics, and even start soil-based farming.

People reach out to Anuradha on LinkedIn and Facebook for advice.You may also reach him through +94 78 823 6376 or send him an email at [email protected]

We’ve realized we’re well past our time. Though there’s much more to learn from Anuradha, we save it for the future.